CNC systems - optimizing production

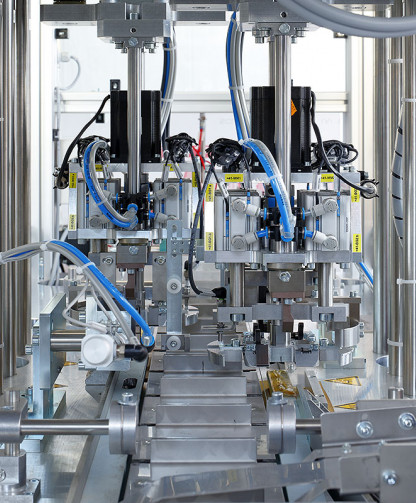

Nowadays machine tools in large production plants in the industrial sector are generally controlled electronically. Because of this, so-called computer numerical control (CNC) has become the industrial standard. This computerized control of machines, which is mainly used in the production and fabrication of serial or individual parts, has several benefits: It streamlines axis movement, thus making tools faster and more accurate. CNC is used in varying industries today, whereby each linked machine tool performs different tasks. At Mack Automation we would be happy to assist you in setting up CNC systems at your company so that you can benefit from a plus in speed and production capacity.

Increasing production volume as well as maximizing precision is an economic focal point in many industries. In order to succeed in the marketplace, production must be continuously optimized and adapted to changing conditions or requirements. This is why CNC systems long ago became standard in manufacturing. In order to be able to benefit from CNC long term, their implementation is of crucial importance - not just the technical requirements regarding hardware and machines, but above all the corresponding software is vital. And this is precisely where Mack Automation comes into play for your project: We take care of the integration of user-friendly systems customized to your project, thus guaranteeing you a plus in efficiency. Contact us.

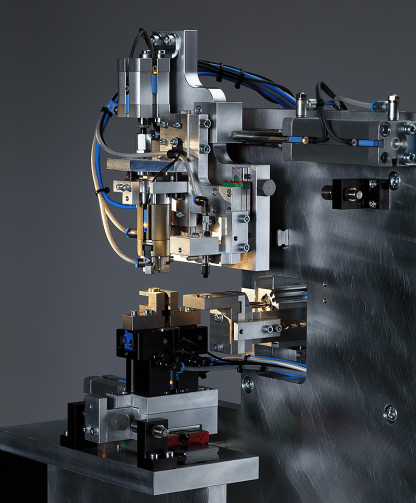

The use of computer-controlled machine tools in production plants is now considered the norm and is being implemented across industries. Nonetheless, the plus in speed and precision that should come with CNC systems can only be 100% achieved through project requirement individualization. As every project and production plant is unique and determined by individual factors, run-of-the-mill solutions lead to a loss of effectiveness. Accordingly, when it comes to CNC, at Mack Automation we believe that modernity and success can only be guaranteed through individuality.

At Mack Automation we have been successfully implementing CNC systems for a wide variety of projects and sectors for many years. In doing so, the systems Siemens SINUMERIK 840D and Beckhoff TwinCAT NC have proven themselves time and time again. You would prefer to implement a different system for your project? We would be happy to familiarize ourselves with other modules and systems in order to achieve the best performance efficiency possible for you.

Adapting and optimizing CNC systems

Whether in the automotive industry or another sector where machine tools are used to produce parts and other components, computer-controlled machines offer many benefits to entrepreneurs. In addition to the increased precision, ease of use of machine tools, swift execution of work as well as great flexibility and adaptability are all advantages. CNC systems cannot only be tailored to individual project needs of your customer once, but can always be altered to changing conditions. Of course, Mack Automation will be at your side as a responsible and experienced partner when retrofitting CNC systems.

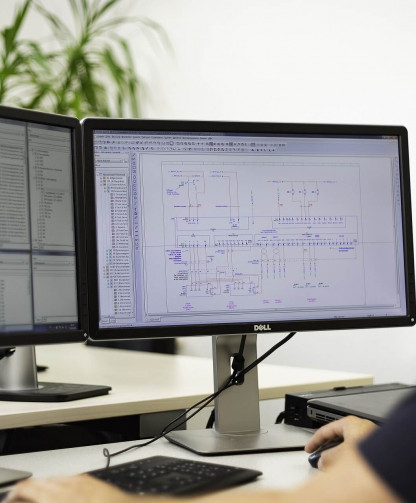

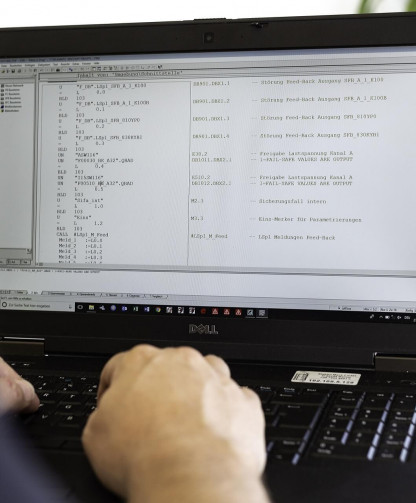

In the fields of hardware design and software construction, at Mack Automation we offer a wide variety of services. The implementation of PLC controls or PLC software construction as well as appropriate visualizations are just as much a part of our daily business as the electronic engineering of complete plants. Benefit from our expertise in versatile fields of activity - we would be happy to explain the benefits of our strategic and integral solutions. Contact us immediately and we will set your machi-nery in motion.