Special Machine Construction - complete solutions according to your reqirements

The reasons for companies to move to automated production vary. Either one wants to rationalize processes and increase productivity. Or one hopes for an increase in the quality of one's own products. Most of the time, it's a mix of both. No matter what your concern is, we take up your task and develop a solution tailored to your needs.

In addition to the analysis of your requirements, you will receive advice on the efficient implementation of your request right from the start. Together we find approaches and ideas how your individual machine has to be designed to meet the expected requirements. With the construction and testing of prototypes, we offer you the opportunity to carry out initial production runs and evaluate the results.

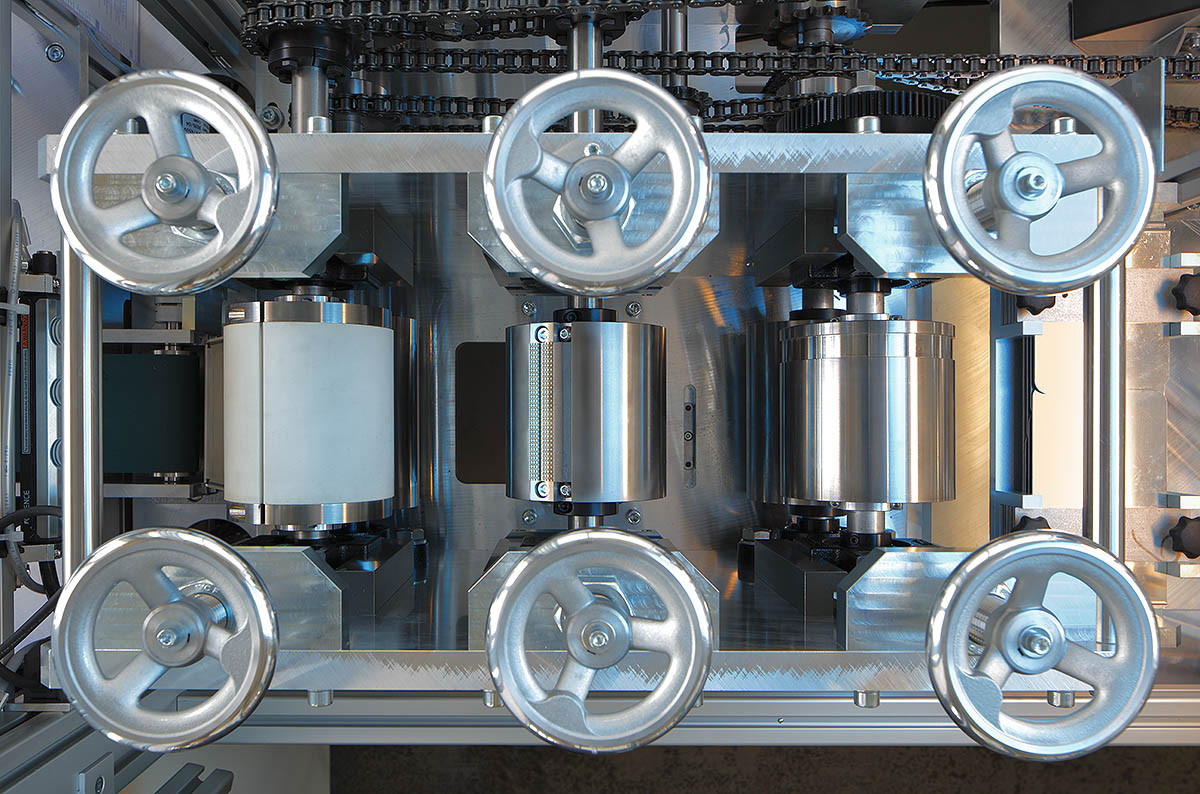

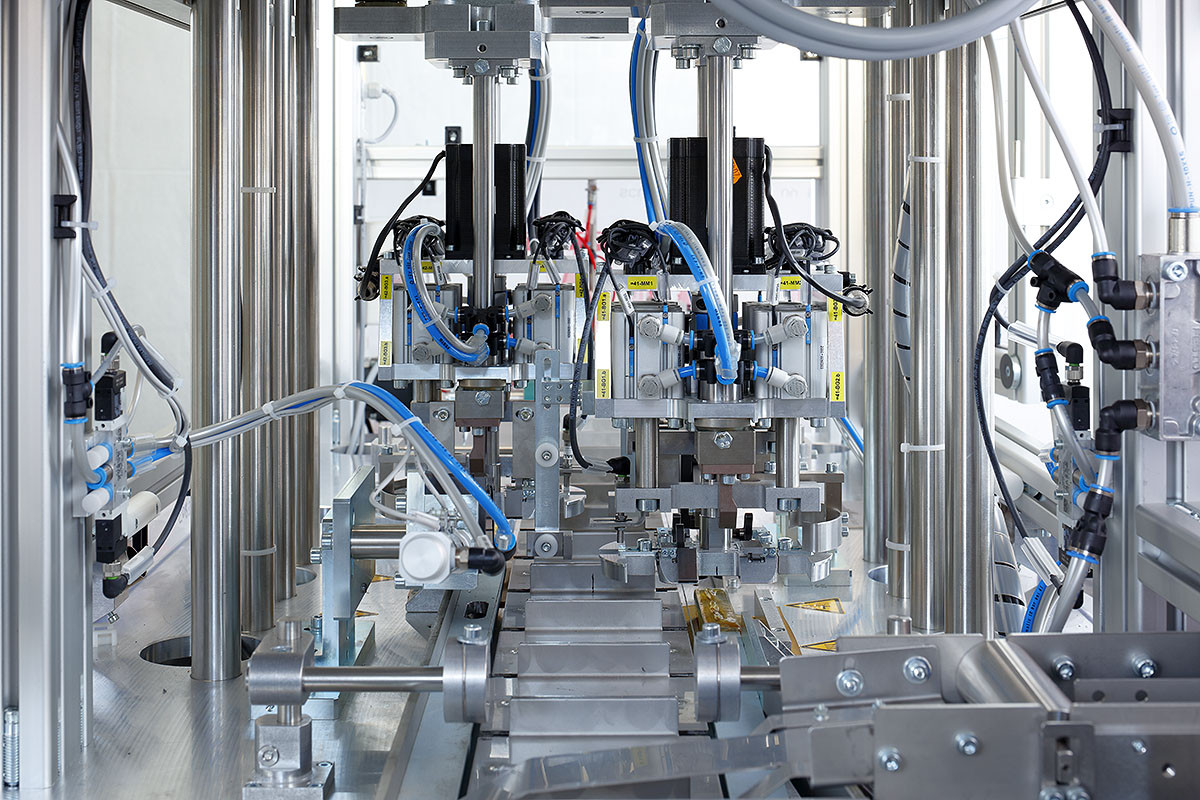

Our know-how covers numerous processes that can be used as part of your overall application, these are for example: separation and feeding of parts, joining and cutting operations, welding, dosing and potting, marking, robotics handling. If necessary, we consult other solution providers for new requirements.

But whether you want to get a prototype first or need a machine integrated into your production process right away, Mack Automation is your one-stop shop for special machine engineering. From development and design, through project planning and commissioning, to training of operating personnel, production support and technical service after completion of the project - Mack Automation is your complete solution provider.

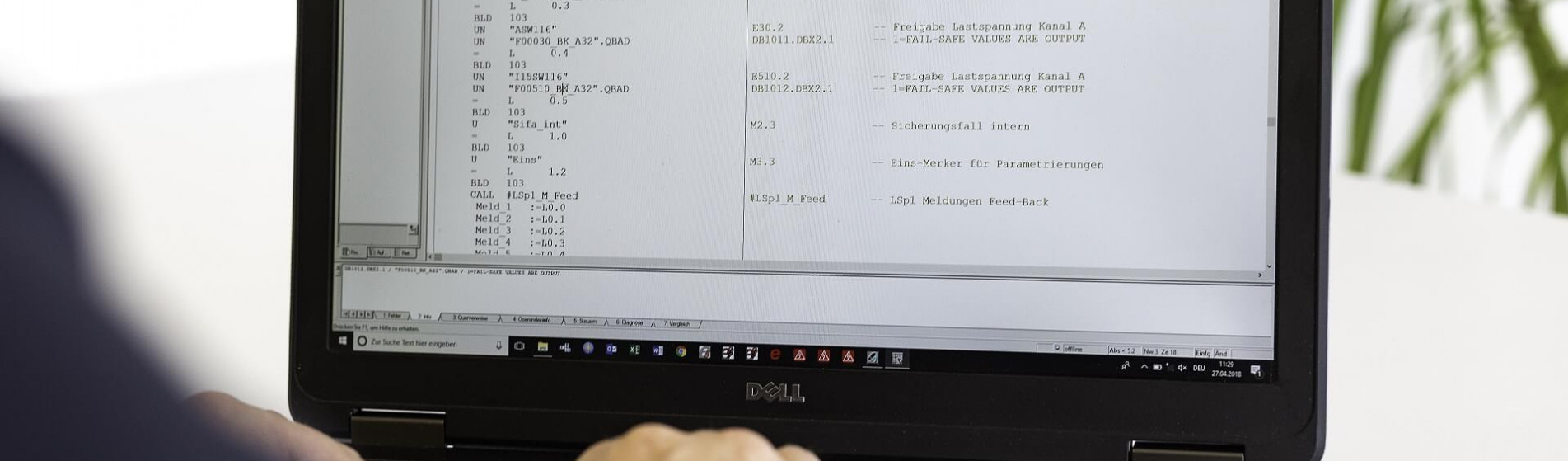

Mack Automation has a broad range of expertise in special machine building and downstream electrical functions to provide you with innovative and reliable solutions, even under the tightest deadlines. Our engineers, technicians and specialists cover the following areas of expertise:

- Plant design

- Development

- Mechanical and electrical design

- Manufacturing

- Installation

- Machine commissioning

- Service and maintenance

For you as a customer in special machine construction, it is important to know that we can support you in all your requirements. Often only a few "centimeters" are missing to solve a tricky problem - but exactly those make the difference. Therefore, here is an excerpt of the processes that are used again and again in our machines:

- Measuring and testing

- Dosing

- Welding

- Potting

- Marking

- Separating and feeding

- Picking up, transporting, depositing

- Image processing

- Integration of process control systems

We can't do everything - but we make a lot of things possible.

- Manual workstations

- Assembly systems

- Handling systems

- Test stations