Welding lines - precision from the very first moment

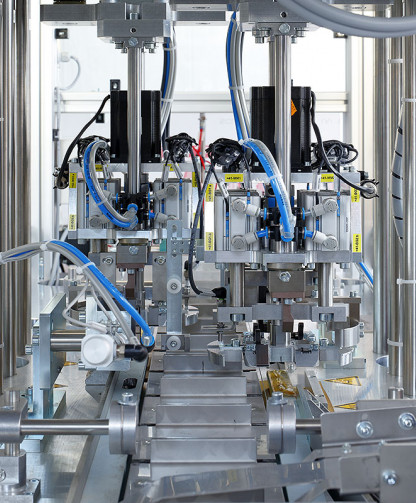

Machinery and production equipment must always be precise and accurate to meet all objectives. This is especially true for modern welding lines. Above all in the automotive industry, welding lines are an integral part of industrial automation technology and must always deliver customized work results of the highest precision during operation. At the same time they should be easy to use and put as economically as possible into operation. At Mack Automation, we not only commission your welding lines according to these criteria, but also in accordance to all other specifications.

The commissioning of welding lines should be proactively planned and, above all, well structured regarding chronological realization. Our extensive experience of more than 40 years of company history is the decisive foundation that provides the necessary planning security the installation of your welding lines requires. On-time delivery and technical know-how are just as standard here as international locations around the world. Whether initializing a completely new welding line or a possible plant relocation, we are by your side. Contact us.

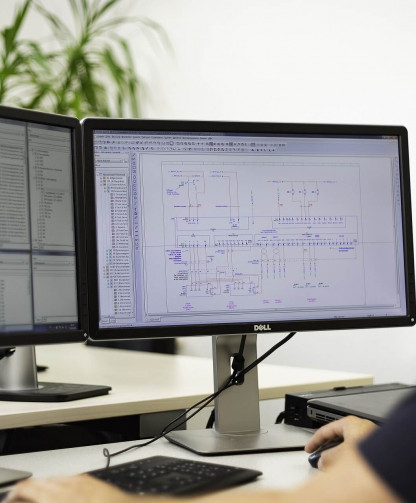

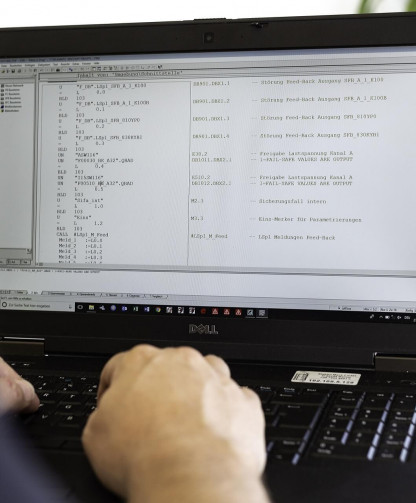

Initializing welding lines is not simply implementing hardware and installing and setting up appropriate software. Interfaces must be created and cycle times coordinated to ensure the smooth functioning of welding lines. As a professional service provider, Mack Automation simultaneously documents all tasks extensively. So you as a project manager and your customer are able to reconstruct individual measures and results step by step.

The commissioning of new welding lines should mean more profit for your client’s company as well as serve as an investment in the future. This makes it all the more important to not lose time during start-up and avoid additional financial burdens. The commissioning schedule is of particular importance in order to optimally coordinate all related work steps and prepare for the complete start-up of the system. Since Mack Automation not only has years of experience implementing welding lines for numerous projects and customers throughout the world, but also offers all start-up related services from a single source, you can rely on our schedule adherence.

Step by step welding line initialization

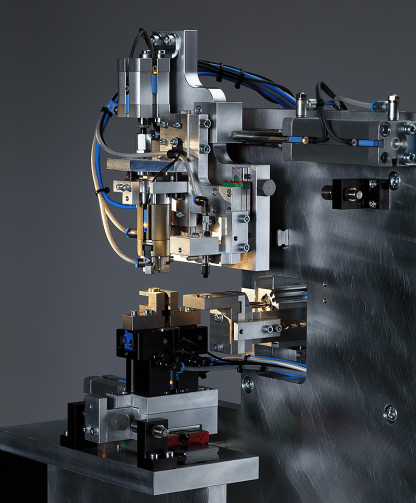

Just as with production and process plants, welding lines are composed of many different components. The complete fabrication of customized components producing precise results is achieved through the finely tuned operation of the individual elements of the welding line. Only if the individual elements are in perfect unison can you and your client count on the welding lines. For this reason, at Mack Automation we always carry out a corresponding analysis during welding-line initialization as part of our start-up support. With its help, flaws can be detected and resolved immediately. This avoids unnecessary idle time as well as the need for reworking.

At Mack Automation, our team offers you a plus in service. Through our schedule adherence and plant optimizing techniques, we guarantee a maximum in planning reliability and efficiency. Our experienced employees are happy to assist you throughout the world. Thanks to short lines of communication and well-managed information exchange, you can leave the work to us and verify the status of your projects with pinpoint accuracy at all times. This keeps you in full control while knowing the individual steps are in good hands. We would be happy to tell you more about our services and methods. Contact us.