Production plants - optimal results thanks to a successful start

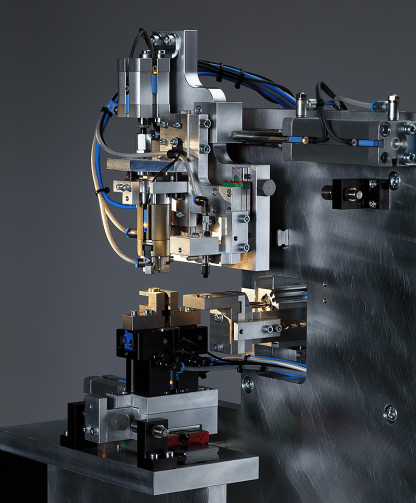

Production plants are used in many industries for varying purposes. Whether food or components for car parts suppliers—depending on the objective, production systems are characterized by different segments and machines. The commissioning of a complete system requires a certain amount of preparation and comprehensive technical expertise. Only a smooth start of a production system guarantees the investment is worthwhile from the beginning. This makes it all the more important for you to rely on an experienced partner for plant initialization as part of your project: At Mack Automation, we have been commissioning production plants for a wide range of customer segments in various industries for many years. We would also be happy to support your needs.

For uncomplicated commissioning of production plants, it may be necessary to check the interaction of individual elements of the plant before actual initialization. This is why, if desired, we test your customers' production facilities virtually in advance. In this way any weaknesses, errors or potential optimization can be detected in advance. This saves time and money. Thanks to our trained eyes as well as our background in more than 40 years of experience in automation technology at Mack Automation, we quickly recognize where improvements can help to optimize cycle times, reduce material waste or improve work precision. The actual initialization of the production plant is then carried out on your behalf complete with these system optimizations. Talk to us.

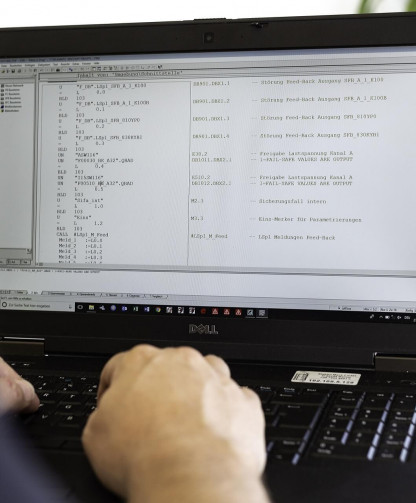

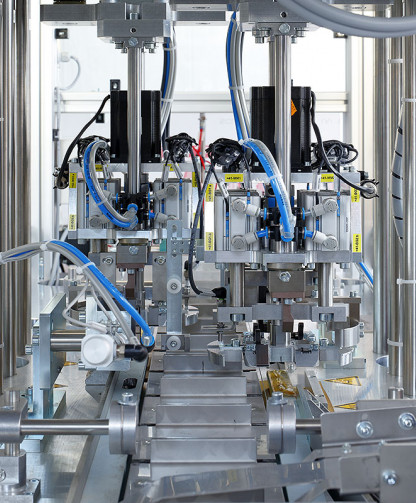

When a production plant is put into operation, it is not just about having a smooth procedure, but also about the optimal functioning of the entire system. This is why we divide commissioning into different phases: Cold commissioning is usually carried out manually and serves to gradually activate the system. During warm commissioning, all mechanical and electrical functions of the plant are checked. Individual elements of the production system are monitored at this time to test if they are really functioning properly.

At Mack Automation, we put a lot of effort into production plant start-up in order to provide you with a plus in security and service. Launch support not only includes the phase-in commissioning itself, but also includes subsequent cycle time optimization. This is where our on-site employees examine the various production steps to determine which are in perfect unison and where idle times or other potential for improvement can be found. Subsequently, appropriate measures are immediately taken on your behalf in order to optimize the settings of the entire production system directly on-site.

Smooth and effective production plant initialization

Production systems are diverse and must be dealt with individually. Every production plant consists of a unique set of elements and machines. These individual components must be taken into account when commissioning production systems. This also applies to the purpose of the respective plant. At Mack Automation, we are committed to multi-stage initialization of production systems in order to guarantee a smooth process and to be able to directly identify and implement potential for optimization. This provides you with a plus in planning security: Not only are you able to work with a specific schedule, but you also know that the production systems put into operation really function how you expect.

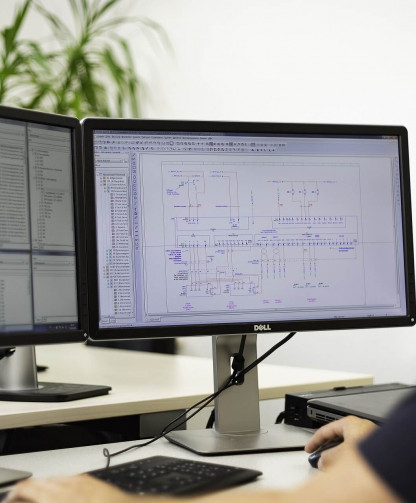

Mack Automation not only offers you the experience of more than 40 years of business activity in automation technology, but also the advantage of face-to-face and individual support. In addition, you benefit from our field expertise and our diverse services: We not only commission newly planned production facilities, but also take care of electronic engineering, hardware installation or software development in advance. This saves you a lot of time and energy during the planning and implementation phase of the project, as you only communicate with a single contact, which guarantees short information paths and individual support. We would be happy to explain to you which projects we can realize for you. Please get in touch with us today.