Welding robots - more power thanks to automation

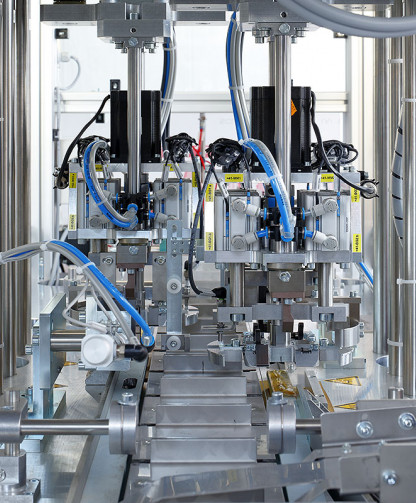

In industrial production, various industrial robots can be integrated as precision and performance enhancing elements in existing or newly designed systems. Often the focus is on so-called welding robots, whose main task is a part of their name. At Mack Automation we have been specializing in programming and optimizing welding robots in industrial plants for years and can get maximum efficiency out of your project or the production of your customer.

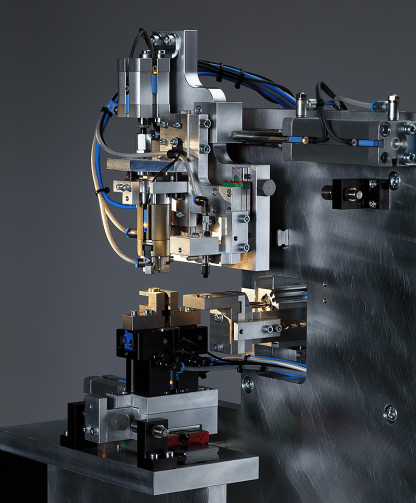

Welding robots are used in various industries for different tasks. However, many of our clients are first and second tier suppliers of the automotive industry. But at the same time, applications in other industries are possible. Welding robots can be oriented differently according to the production target: Depending on the selected model, welding robots are responsible for seam welding, stud welding, laser beam welding or resistance welding. In order to ensure maximum productivity of the welding robot within the plant, it is important not only to select the right system, but also installing the appropriate program. For this purpose, Mack Automation is by your side as an experienced and reliable partner with a plus in commitment.

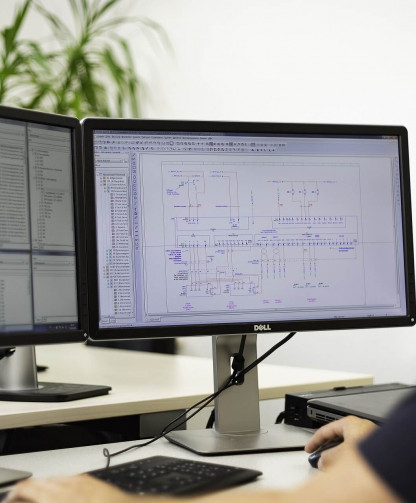

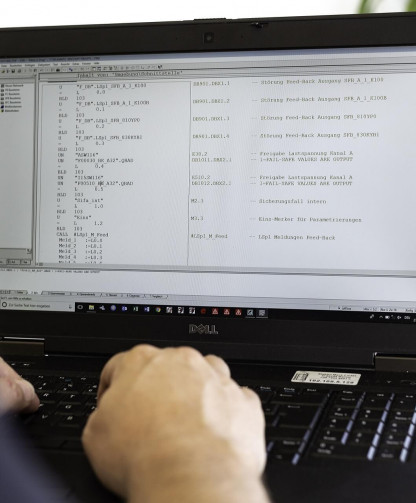

To ensure the efficiency of welding robots, it is important to rely on the latest generation of robots from proven systems. We can look back at positive experiences along with our partners from different industries using developments of ABB, FANUC and KUKA. You prefer welding robots from another manufacturer? In this case, at Mack Automation we would also be very happy to assist you as incorporating systems from other manufacturers is no problem for us. It would be best to get in touch with us right away and together we will discuss the possibilities of our Robot Programming.

The various advantages of using welding robots are obvious: For one thing, ideally selected and optimally programmed welding robots enable more precise work with significantly reduced cycle times. The latest robot systems reduce unproductive processes or movements to a minimum and can increase the efficiency of the entire production chain many times over. Also, modern welding robots have maximum energy-efficiency and thus help to reduce costs even during operation. The investment in a welding robot can pay for itself after a short time and lead to significant profit increases.

In order to help an industrial production plant to a maximum of efficiency, it is not always necessary to completely replace robot systems. Alternatively, it is often worthwhile to revise existing systems. With new or modified programming, welding robots can, for example, deliver more precise work results with shortened cycle times or take on new tasks and applications. We are happy to reprogram existing welding robots.

Adapting welding robots to tasks

Welding robots from different manufacturers perform different tasks: Consistent welding quality, which does not require extensive post-processing, is the optimum result. At the same time, a high axis speed and the avoidance of unproductive movement should allow for shorter cycle times of work processes. In order to guarantee this, it is important to perfectly plan the integration of a welding robot from the start. With our extensive knowledge of industrial robot systems we can assist you. We examine your planned project and support you in finding the right welding robot to integrate precisely into the system.

Your customer already owns high-efficiency welding robots that unfortunately do not bring the desired effects in the existing system constellation? With the aid of cycle time analysis, we help to identify existing weaknesses in plants. Thanks to subsequent reprogramming, it is possible to achieve the desired effects again and at the same time save costs.

At Mack Automation, we are the ideal partner for you when it comes to all-in-one industrial system solutions. That is why we focus not only on welding robots in Robot Programming, but also integrate and program handling robots into new or existing systems on request. In addition, with more than forty years of experience, we are also at your side for hardware design, plant commissioning and the implementation of industrial assemblies. We would be happy to explain the possibilities our range of services can offer you. Just contact us.