Industrial robots - increasing efficiency on many levels

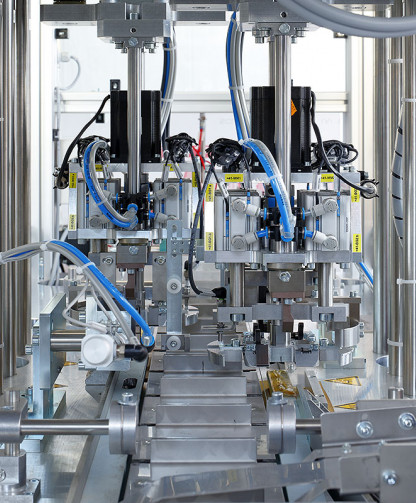

With industrial production, it is always about maximum efficiency: faster production, optimized work processes and more accurate assembly results are examples of increased efficiency. Many of these objectives can be met using so-called industrial robots. Integrating industrial robots into your customer's existing systems or planning them into a newly designed plant is a part of our job as much as optimizing robot programming so that existing industrial robots can be used better, faster and overall more effectively.

The term industrial robot is collective and encompasses all robots or robotic systems used in the industrial sector. Accordingly versatile are the possible specifications of industrial robots as well as the tasks that can be accomplished by these machines. In general, for every industrially motivated project in production or logistics, there is an industrial robot for the job. We have had along with our partners particularly good experience with systems from the manufacturers ABB, KUKA and FANUC. As a flexible and customer-oriented service provider, at Mack Automation we are also more than willing to familiarize ourselves with the systems of other manufacturers to achieve maximum efficiency for your customers and your project.

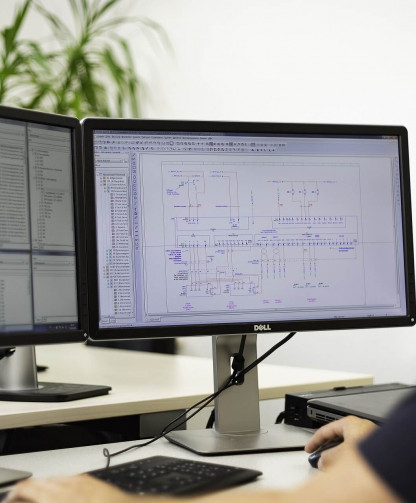

In general, there are many fields of application for industrial robots: At Mack Automation we are specialized in the integration and programming of welding robots and handling robots for use in production as well as logistics. The wide range of possible applications for industrial robots can be found in the Industries section, and you can also get an overview of the sectors in which our robotic systems are already being successfully used. Generally, we undertake the electrical installation of robots, the programming of the controls and the robots themselves as well as the complete commissioning of the entire system including cycle-time optimization for you. Feel free to contact us for more information.

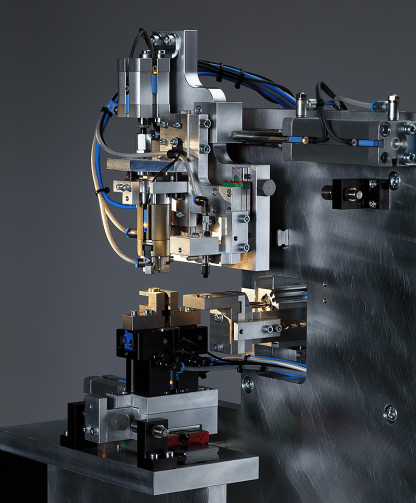

Industrial robots or robot systems used in industry have steadily developed in recent years and are able to perform various tasks with maximum precision and effectively optimized cycle time. At Mack Automation we offer programming and commissioning for robot systems that can be used for the following tasks: painting, measuring, grinding, cutting, welding, joining and handling. This results in a wide range of applications for your customers in varying industrial sectors.

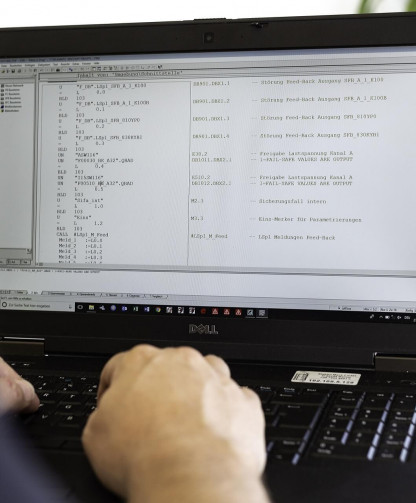

Your customer wants to optimize production processes to be able to use existing systems even more efficiently? From time to time, reprogramming existing industrial robot systems is recommended to adapt them to new challenges and work processes. We would also like to complete such tasks for you, so that the productivity of your customer's plant is increased to a maximum once again.

Customizing and adapting industrial robots

The application range of industrial robots is versatile, yet clearly defined. In order for your customer to benefit from efficiency-enhancing measures throughout their entire system through the use of industrial robots, adapting or customizing the programming is unavoidable. Whether you are planning a handling robot for your customer's plant or think that a welding robot is the better choice, robot systems only become truly productive with optimized programming. This is especially true when robot systems are regularly presented with new tasks. Modern systems are designed to allow for easy reprogramming to ensure that the systems execute the new tasks precisely and efficiently. We would be happy to do this for you and your project.

In addition to proper robot programming, the seamless integration of industrial robots in technical plants is another important factor. The optimization of cycle times can only occur if individual systems in the plant are coordinated with each other. A cycle-time analysis or a cycle-time optimization can be extremely helpful. This means we not only assist you in designing new plants, but also enhance or realign existing systems for you in the interest of your customer.

You are looking for an experienced and specialized partner with a plus in dedication for implementing ideas for technical systems? When it comes to industrial automation technology, at Mack Automation we have been supporting companies and partners from various sectors for more than forty years. Innovation and individuality are our focus, whereby we not only deal with robot systems and the integration and programming of industrial robots, but we also construct hardware, commission plants and develop software for projects. This is how you can benefit from numerous services from a single source. If you have any questions about our service range, the use or programming of industrial robots, we would like to hear from you.