Handling robots - customized automation

You are looking for automation systems that enable your customers in logistics or production to have more resource and cost efficient work processes to optimize overall efficiency? The solution is in modern technology such as handling robots. Over the past few years, these innovative machines have been able to establish themselves in many branches of industry, where they carry out a wide variety of tasks depending on the field of application.

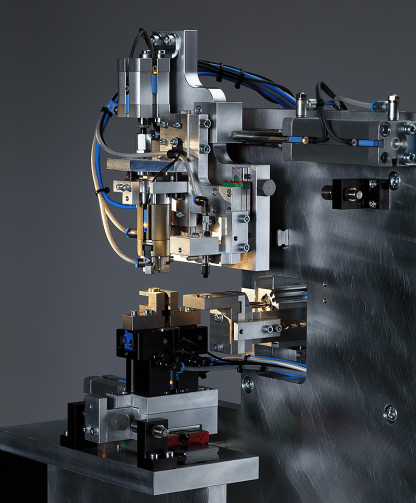

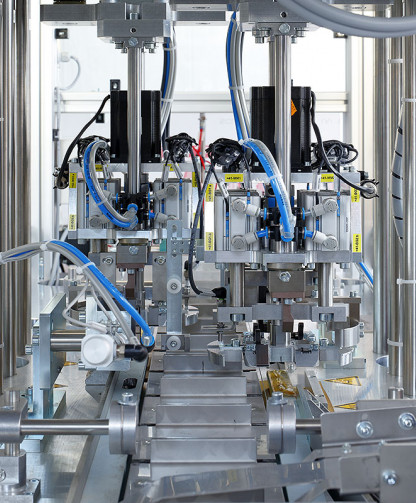

We integrate handling robots into the pre-existing systems of your customers on your behalf so that they can accomplish certain types of tasks more precisely with faster cycles. Whether you are looking for a handling robot for logistics or industrial production is of secondary importance: We program the desired handling robot in such a way that it autonomously handles stacking and palletizing, performs the assembly of components or revolutionizes machine loading at your customer's company. Handling robots can also take over the transfer between different processing stations on request.

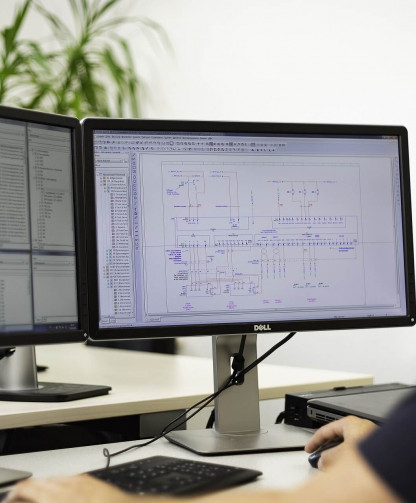

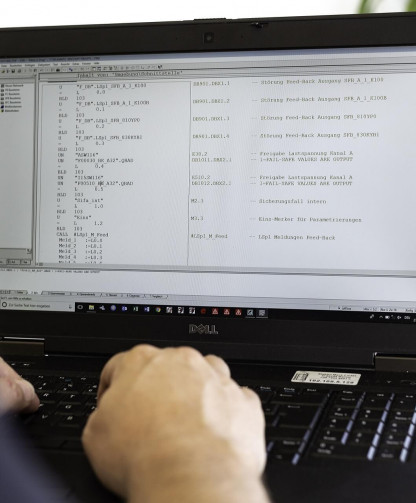

Regarding robot programming and modern handling robots, at Mack Automation we have extensive experience with machines from renowned manufacturers and systems such as ABB, FANUC and KUKA. Tailor-made solutions for machine selection and programming are always our top priority. This is why we also like to familiarize ourselves with robot systems from other manufacturers - to develop the best efficiency-enhancing measures for your project and to take the individual business needs of your customers into account at all times. You have questions about robot programming or are interested in the application possibilities of handling robots? Please contact us for non-binding consultation.

Handling robots in logistics as well as in industrial production mean far-reaching advantages: Through customized programming they deliver permanent and continuously accurate results of the highest quality. In addition, handling robots can perform identical tasks in shorter cycles and accordingly achieve greater output over the same amount of time. As a result, the sometimes high acquisition costs are recovered after a short period of time and the investment begins to pay dividends.

In order to ensure lasting performance, various developments and innovations often entail far-reaching demands for adaptation. This also applies to the automation processes at the company of your customers: When new tasks are scheduled, the involved systems require a certain flexibility. For this purpose, we are happy to take over the reprogramming of already used handling robots so that the productivity of the system remains guaranteed.

Customization options of handling robots

The selection of handling robots available nowadays is relatively large: Many manufacturers are always creating innovative systems that bring new advantages for increased efficiency. In order to keep costs and benefits at a profitable ratio, you must plan for the possibilities of introducing or expanding automation processes in the interest of your customer. In the end, a handling robot must be seamlessly inserted into an automation system - programming plays a crucial role here and must not be neglected. Because only with appropriate programming will the handling robot perform precisely the tasks that you or your customer have actually planned for it in the system. As experienced professionals in the electronic industry, we not only support you in the selection and integration of the right handling robot, but also take over the programming of the technical equipment for you. This is how you can offer your customers an all-in-one solution, in which all relevant aspects are taken into account so they can always count on a plus in service.

To achieve maximum productivity and efficiency, we also carry out so-called cycle time analysis upon request. This helps to identify existing gaps and close them using individual optimization measures. Our service is accordingly designed to support your customer's project long term, so that the investment in the handling robot is worthwhile for a long time.

As a company, Mack Automation has been committed to implementing innovative and individual customer specifications in industrial automation technology for more than forty years. In addition to plant commissioning, software programming and hardware engineering, we also focus on robot programming. For general questions or specific concerns, we are at your disposal.